Ready to Transform?

If your sugar mill or bioethanol plant is under pressure to reach higher yield, lower energy usage, extend campaign length, or improve co-gen economics – let’s talk.

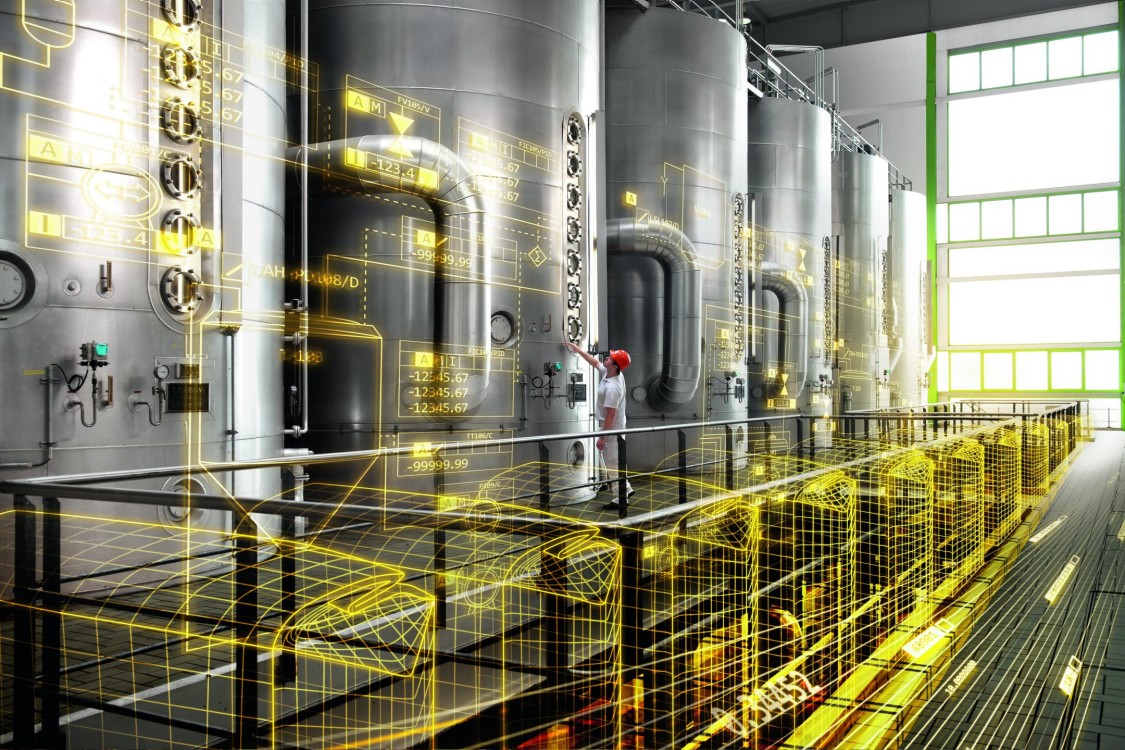

Connect with Visionaize and explore how our AI-driven optimisation platform can be configured for your unique operation.

CoPilot

CoPilot